Injection moulding is the cornerstone of large-scale plastic part production, offering precision and cost-effectiveness.

This process ensures your product’s plastic components are reliable, scalable, and ready for mass production.

Injection moulding is the cornerstone of large-scale plastic part production, offering precision and cost-effectiveness.

This process ensures your product’s plastic components are reliable, scalable, and ready for mass production.

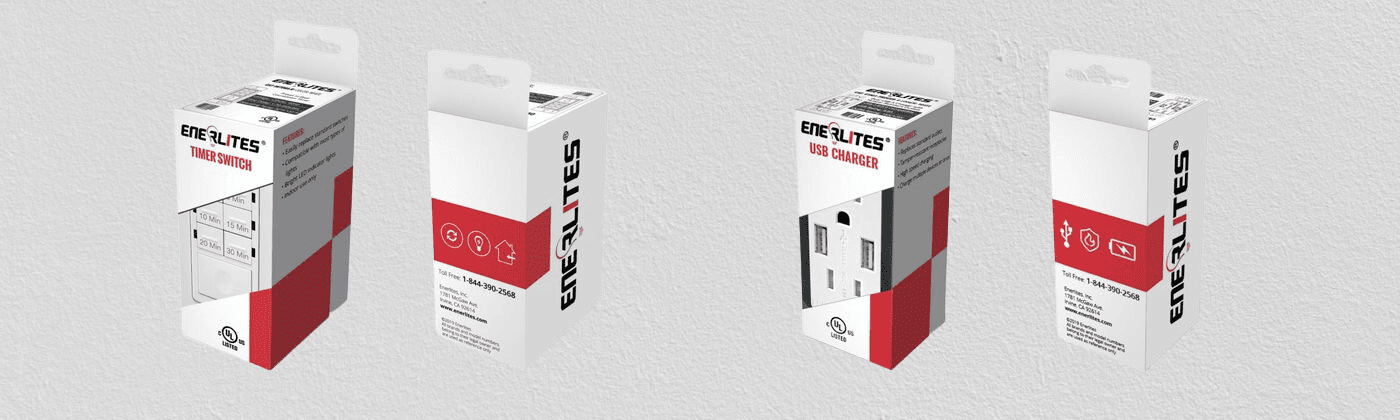

A product that performs well also needs to look and feel professional. Branding elevates your product from functional to memorable.

By focusing on branding, we ensure your product leaves a lasting impression and aligns with your company’s identity.

Efficient manufacturing starts with reliable suppliers. Our global sourcing expertise ensures your product is built with high-quality components.

This step lays the groundwork for a cost-efficient and dependable manufacturing process.

Before scaling production, it’s crucial to verify that your product is fully functional and reliable.

This phase ensures your product is ready for real-world use and manufacturing scalability.

Every product must comply with regulatory standards to enter target markets. We simplify this complex process.

Regulatory compliance ensures your product is legal, safe, and ready to sell in your chosen markets.

A well-planned manufacturing setup is essential for producing consistent, high-quality products.

This step ensures an efficient, scalable manufacturing process that produces high-quality results.

The final step turns your refined design into a market-ready product through full-scale production.

After this final step, your product is ready for distribution, meeting customer expectations and market demand.